6th March 2023« All News Items

A Guide to Sailmaker’s Terms

Sailing has a language all its own. It's evolved over hundreds of years of nautical exploration and warfare, and sailmaking is no exception. We thought it would be helpful to write our own mini dictionary of the terms you're likely to come across when discussing your new sails, so you can know your Aspect ratio from your Warp. (Not quite A-Z)

Sailing has a language all its own. It's evolved over hundreds of years of nautical exploration and warfare, and sailmaking is no exception. We thought it would be helpful to write our own mini dictionary of the terms you're likely to come across when discussing your new sails, so you can know your Aspect ratio from your Warp. (Not quite A-Z)

Aramid: Technically speaking, aramid fibres are long-chain synthetic polyamides(!). In sailmaking terms they have extremely low stretch, which is why they are commonly used in high performance sails. Available in a distinctive yellow colour or Black, Aramid fibres are also known as Kevlar (Trademark of DuPont) or Twaron and Technora (Trademarks of Teijin)

Aspect Ratio: The luff length of a sail divided by the foot length. High aspect sails are tall and thin.

Bias: A diagonal across a piece of fabric at 45-degrees to the warp and fill.

Carbon: An extremely high modulus (low stretch), lightweight, performance fibre used extensively in racing and Superyacht sails.

Count: The number of fibres or yarns per inch in the warp or fill of a cloth.

Creep: The measurement of gradual stretch of a fibre when put under a constant load.

Crimp: Length or waviness added to a yarn when it is woven over-and under in a piece of fabric. Crimp can contribute to the elongation of a fabric under load.

Cross-Cut: A panel layout where the seams run across the sail, perpendicular to the leech.

Dacron: DuPont’s trade name for polyester fibre.

Denier: A measure of the weight in grams of 9000 metres of a continuous yarn. 9000 metres of a 3000 denier yarn weighs 3kg

DPI count: Denier per inch is a method used by sailmakers to define the weight and or strength of moulded / Membrane sails which use filament yarns and fibres. A low DPI number suggests a small or light wind sail and the DPI count increases for larger or heavier wind sails. It is a measure of the yarn content in a particular part of a sail which can be a good way to compare the likely strength of different moulded / Membrane sails as long as the defined DPI measurement point is in the same place on each sail.

Dyneema: Super strong polyethylene fibre made by DSM, up to 40% stronger than Aramid. It is resistant to UV and moisture with good flex properties which makes it a good choice for large cruising sails.

Elongation: The difference between the length of a stretched sample and its initial length; expressed in 1/100ths of an inch.

Fibre: Strand of material used to make a yarn.

Fill: The yarn running across the width of the fabric at right angles to the warp.

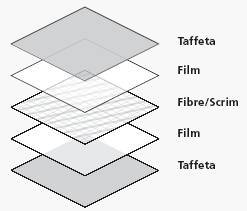

Film: A base layer of Mylar onto which yarns or fibres are applied.

Flex Strength: The ability of a fibre to resist strength loss having been flexed back and forth.

GSM: Weight in grams of a square metre of cloth.

Hand: Softness or firmness of a fabric.

Kevlar: DuPont’s trade name for a family of high-strength Aramid fibres.

Laminate: A Laminate sail is made from a pre-produced roll of cloth. This will then be cut into sections which will be glued, bonded or sewn together to make the sail and build shape according to your sailmaker’s design.

Membrane sail: A saiI is often described as a Membrane when all of the raw materials, including film, taffetas, scrim and fibres, are added to a process which makes a custom sail with the fibres laid out precisely in a “load map”, as specified by the sail designer to suit the customers exact sailing requirements.

Modulus: The measure of stretch or elasticity of a fabric. High Modulus = low stretch.

Mylar: Created when polyester fibres are melted and made into sheets or rolls of lightweight clear film.

Pentex: Modified polyester with less stretch. Sometimes called ‘PEN’.

Polyester: A strong, reliable and inexpensive fibre ideal for cruising and low tech racing laminates, and woven sailcloth.

Primary Yarn Direction: The orientation (warp or fill) in which a fabric is the most stretch resistant.

Radial: A panel layout where the seams and panels radiate out from the corners of the sail.

Scrim: Non woven, formed sheet of yarns held together with resin.

Spectra: A highly modified polyethylene fibre developed by Allied Corp with similar properties to Dyneema and often used in large cruising sails.

Taffeta: A light woven polyester fabric used on laminates to add durability and abrasion resistance.

Technora: A more durable Aramid fibre which is usually black in colour.

Tenacity: The breaking strength of a yarn or fabric stated in force per unit of the cross-sectional area.

Tensile Strength: The ability of a fibre, yarn or fabric to resist breaking under tension.

Threadline: The direction of the yarns.

Twaron: Trade name of Aramid fibre made by Teijin

Vectran: A Liquid Crystal Polymer fibre made by Hoechst Celanese with low stretch and excellent flex properties. Vectran is used in high performance cruising and racing sails where durability is key.

Yarn: Created by combining a number of individual fibres. Yarns in sails are typically made up of 3000 individual fibres which on their own are so small that they are difficult to see with the human eye.

Warp: The yarn running the length of a fabric.